You’ve Heard It Said: Change Is The Only Constant. Consumer Tastes and Habits Are Perfect Examples.

To master change, you need to partner with someone with proven capabilities, demonstrated experience, and an integrated solution delivery model that culminates in a smooth transition and full operational capability quickly.

With other providers, there may be third-party consultants with finite experience working between professional hand-offs. But at Americold, our in-house designers, supply chain engineers, and Program Management Office are unified in our solution-delivery goal and not competing for your dollars.

The result? You… happier.

Design, Build, Operate.

At Americold, we take pride in being able to bring our customers’ supply chains to life, and being able to support the launch transition through our Program Management Office.

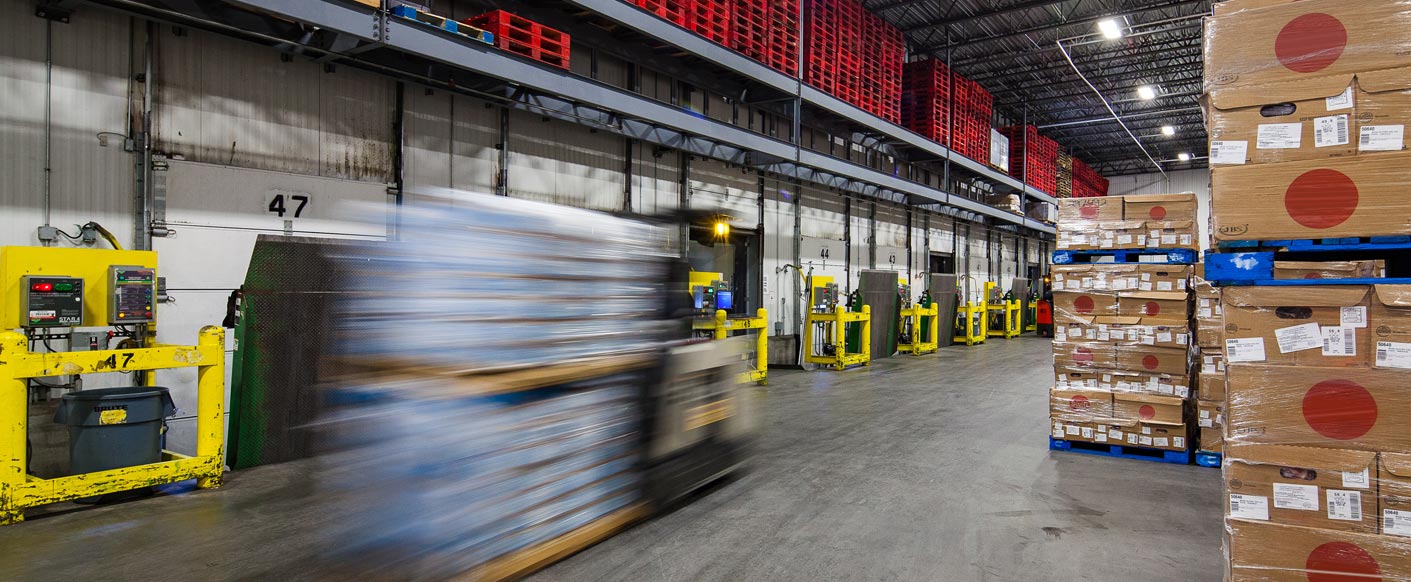

High Performance, Highly Efficient

Fifty years of experience. Soon-to-be six Regional Consolidation Centers. A provider with stability, experience, and a ubiquitous network – one that is technologically-integrated and seamlessly-connected for real-time supply chain control, tracking, and on-time, in-full delivery. All of these resources provide you with customized supply chain solutions that help you respond to market challenges and meet customer demand.

Fifty years of experience. Soon-to-be six Regional Consolidation Centers. A provider with stability, experience, and a ubiquitous network – one that is technologically-integrated and seamlessly-connected for real-time supply chain control, tracking, and on-time, in-full delivery. All of these resources provide you with customized supply chain solutions that help you respond to market challenges and meet customer demand.

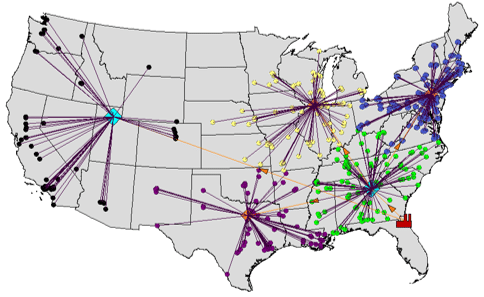

Supply Chain Optimization

If you need to have shipments consolidated from multiple sources or need distribution to multiple customers, with Americold you can do it all. We’ll review the journey of each SKU to determine its optimal path, and others like it. We’ll present you with the “ideal” supply chain map based on your actual ordering history, product origins and destinations, and forecasts, and feature prime inventory pile locations, restocking timelines, and fulfillment possibilities to achieve your customers’ key performance indicators. And we’ll show you our plan for how we could implement the solution for you, whether it be a supply chain Design, Build, Operation, or all three.

Inventory Right-sizing

Our supply chain engineers determine the positioning of optimized inventory levels at each of your forward distribution nodes through SKU rationalization and velocity analysis in order to provide higher customer service levels for fulfillment.

We’ll align outbound volume by region, reflect weekly demand and seasonality for each of your SKUs, model inventory flows at normal and peak rates, and determine optimal inventory levels that take into consideration current stock, safety stock, and total stock volumes. We can even evaluate the effectiveness of value-added services for you.

Our supply chain engineers determine the positioning of optimized inventory levels at each of your forward distribution nodes through SKU rationalization and velocity analysis in order to provide higher customer service levels for fulfillment.

We’ll align outbound volume by region, reflect weekly demand and seasonality for each of your SKUs, model inventory flows at normal and peak rates, and determine optimal inventory levels that take into consideration current stock, safety stock, and total stock volumes. We can even evaluate the effectiveness of value-added services for you.

An Integrated, National Network

Our integrated national distribution network allows you to service your customers wherever they are by staging inventory closer to your stores or distributing from one inventory location within our network. Your orders may have multiple sources, but with our technologically-integrated, seamlessly-connected nationwide operations, they will be tracked, protected, and delivered –quickly and cost-efficiently, no matter how complex they appear to be.

Our integrated national distribution network allows you to service your customers wherever they are by staging inventory closer to your stores or distributing from one inventory location within our network. Your orders may have multiple sources, but with our technologically-integrated, seamlessly-connected nationwide operations, they will be tracked, protected, and delivered –quickly and cost-efficiently, no matter how complex they appear to be.

Multi-temperature Capabilities

If you need to have shipments consolidated from multiple sources and across multiple temperature classes, you can do it all with a single solution at Americold.

Frequently Asked Questions

VIEW ALL FAQSWhere does Americold have Facilities?

Visit our Facilities page to see a map of our locations and see which one is closest to you and your business.

Does Americold lease or own its facilities?

Americold primarily owns its facilities, though in some cases Americold provides staff for customer-owned facilities or leases buildings if that’s a better fit for a specific program or location. Learn more about our sites on our Facilities page.

Can Americold manage a pallet provider program for its customers?

Yes, Americold can manage your pallet program for both inbound and outbound pallets as well as provide weekly reconciliation with the pallet provider team.

What ancillary/value-added services does Americold provide?

Americold offers a full range of ancillary/value-added services for its customers – the following are just a few examples: manifesting/take weights, slatting & de-slatting, manual order entry, USDA Services, case and each picking, aisle-ready pallet preparation, date stamping, light processing, blast freezing, and tempering. Discover more by clicking here . We can develop new processes and services to compliment your products as well – you have only to ask.

Ready To Get Started?

Contact us online now or call us at 888-808-4877