At Americold, we take pride in being able to bring your supply chain to life.

Your supply chain quandary could be stopping you in your tracks. You may be unable to move past day-to-day operations to fulfill orders on hand, and peak season is coming.

We’re here to help. We’re dedicated to delivering more than just your products – we want you to have an optimized solution, customized for your order fulfillment cycles. Whether it be a simple redistribution of inventory to take advantage of macro economics, or a full scale re-evaluation of end-to-end inventory optimization, including new building construction and management, we can do it all through our three-phase approach–Design, Build, and Operate.

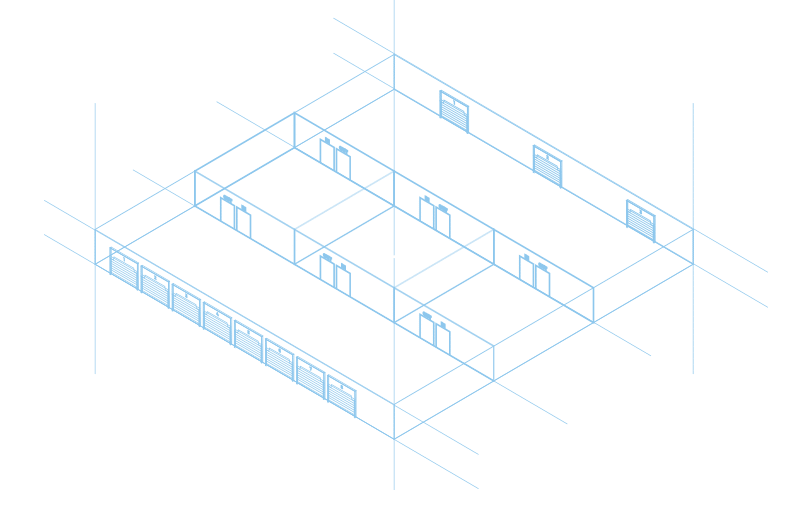

Design

Our solution-development process is structured as a collaboration with you to obtain your requirements and understand your end-to-end supply chain needs. We listen first, then develop. Our thorough review includes: network strategy and location optimization, transportation costing, warehouse retrofit and/or new design evaluation, and operational management requirements. And our in-house architectural and engineering teams evaluate and help justify the use of full- or partial- automation, where we believe there is a value-add for you.

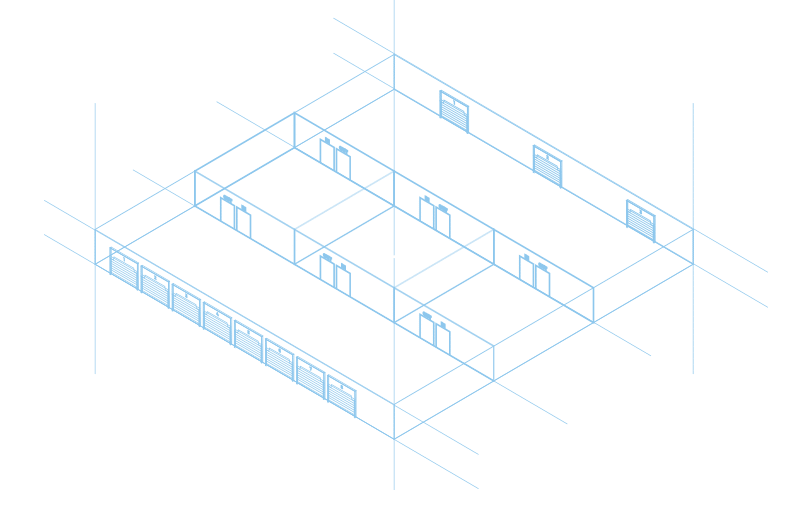

Build

We’ve created our own implementation methodology called Integrated Program Launch (IPL) that’s driven by a series of readiness checks and tollgates – an established process for best-in-class solutions. This proven methodology brings order to typically stressful transitions to new processes, and enables our Program Management team to launch your new supply chain successfully with minimal service disruptions. We provide broad-based visibility to the timeline for all of your stakeholders and reduce the learning J-curve as much as possible.

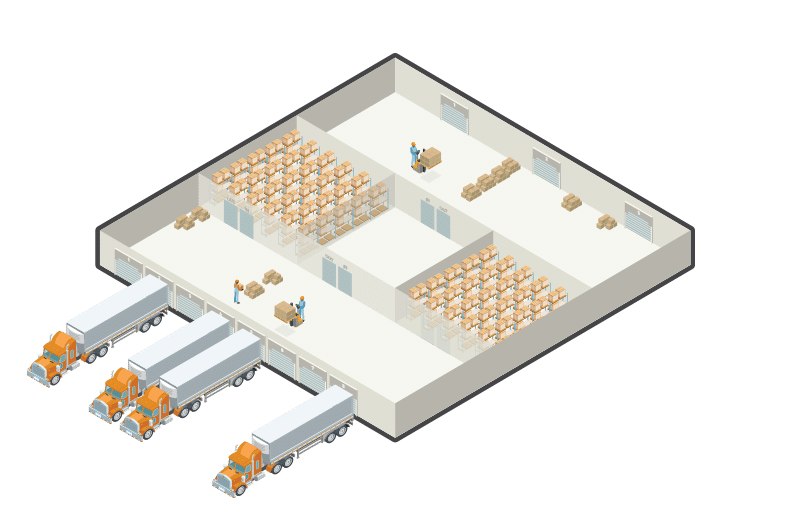

Operate

Our integrated Design, Build, Operate approach eradicates conflicting hand-offs between typical supply chain consultants only concerned with their own scope of activities. We’re invested from concept through to delivery and operation, and our process works extremely well.

Upon delivery, our Americold Operating System (AOS) takes over activity management. AOS is designed to drive supply chain innovation and maximum value for you by striving for continuous improvement from uniform operations, standardized across our network.

In-house, interconnected PMO

Americold's Program Management Office relieves the pressure on the most sensitive of events: supply chain transition.

With more than 100 successful, large-scale supply chain transitions in the last few years, Americold’s PMO has the experience, dexterity, and vision to implement supply chain transitions by product line, store, or geography for minimal disruption so that you can reap benefits sooner.

Our value proposition for you:

- The largest portfolio of integrated temperature-controlled warehouses available

- Mission-critical element of the global food infrastructure

- Innovative solution design capabilities throughout the cold chain

- Delivery into one of our existing facilities, or a turn-key solution designed for you

- Broad network that when fully utilized improves service windows and eliminates supply chain nodes

- World-class quality of service and offerings, including network strategy optimization and transportation programs

- Track record of partnering with customers to support their successful growth initiatives

- Best-in-class IT platform and i-3PL Supply Chain Control system

- Best-in-class cold chain intelligence

- Value adding service offerings such as blast freezing, tempering, light processing, assembly, kitting, sequencing, repacking, labeling, date-coding, and more.

- The largest portfolio of integrated temperature-controlled warehouses available

- Mission-critical element of the global food infrastructure

- Innovative solution design capabilities throughout the cold chain

- Delivery into one of our existing facilities, or a turn-key solution designed for you

- Broad network that when fully utilized improves service windows and eliminates supply chain nodes

- World-class quality of service and offerings, including network strategy optimization and transportation programs

- Track record of partnering with customers to support their successful growth initiatives

- Best-in-class IT platform and i-3PL Supply Chain Control system

- Best-in-class cold chain intelligence

- Value adding service offerings such as blast freezing, tempering, light processing, assembly, kitting, sequencing, repacking, labeling, date-coding, and more.

From the ground up

In a matter of months, Americold’s team initiated and completed the construction of the 120 foot high, 6-crane, -20 degree Fahrenheit convertible room, 20,000 pallet position extension to support our food producers shipping products throughout the Ohio Valley region. The expansion compliments the traditional warehouse operations already on-site just southeast of the city of Indianapolis.

Design, build, operate your next project with us!

Contact us online now or call us at 888-808-4877