More than just cold storage.

Americold’s facilities accommodate a wide range of temperature-controlled supply chain activities for anyone needing the support. We offer shared space or dedicated resources and all of the advantages that go along with them, and our suite of value-added services can make your products work while waiting to fulfill orders.

Learn more about our breadth of capabilities below, and then contact us to discuss how we can optimize your supply chain.

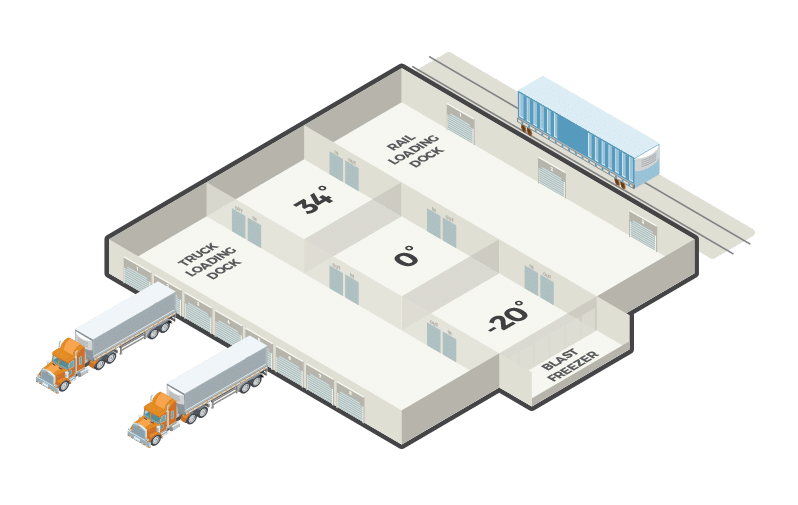

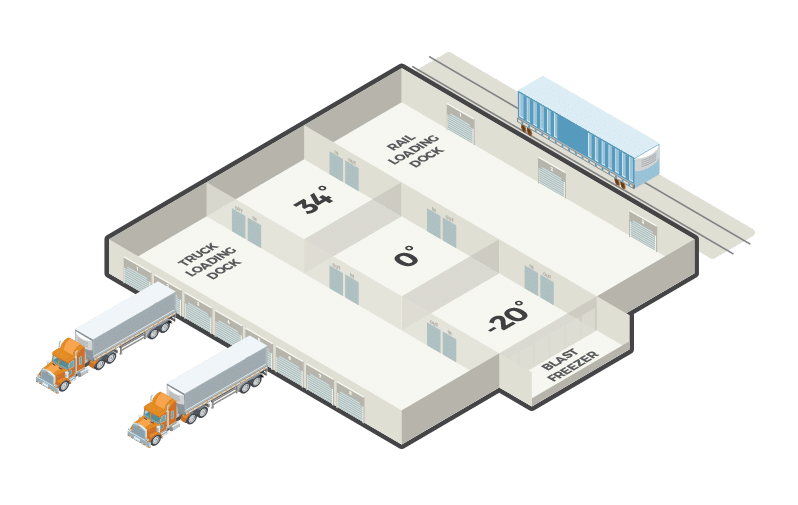

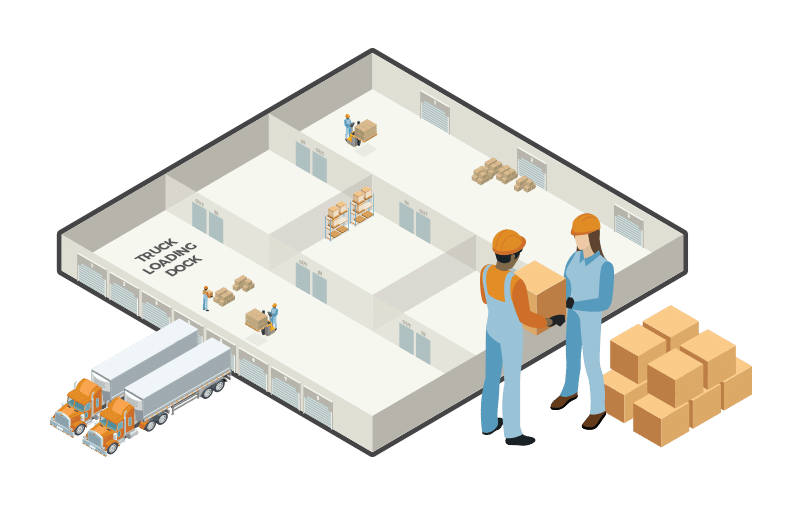

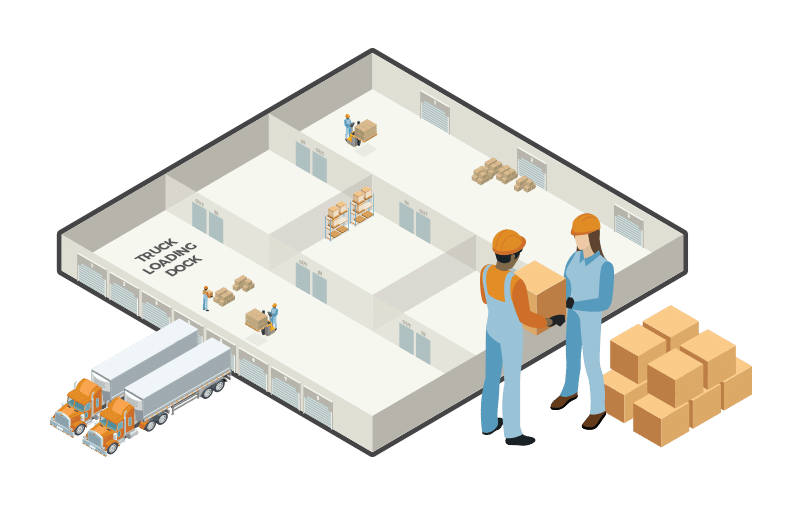

Public warehouses

These facilities support local and regional storage and value-added service requirements. We can offer simple storage or a full temperature-controlled supply chain operation from these sites.

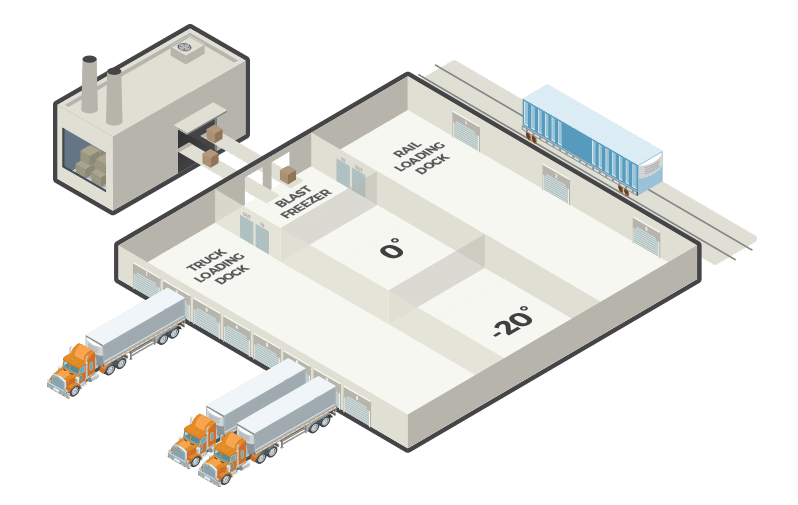

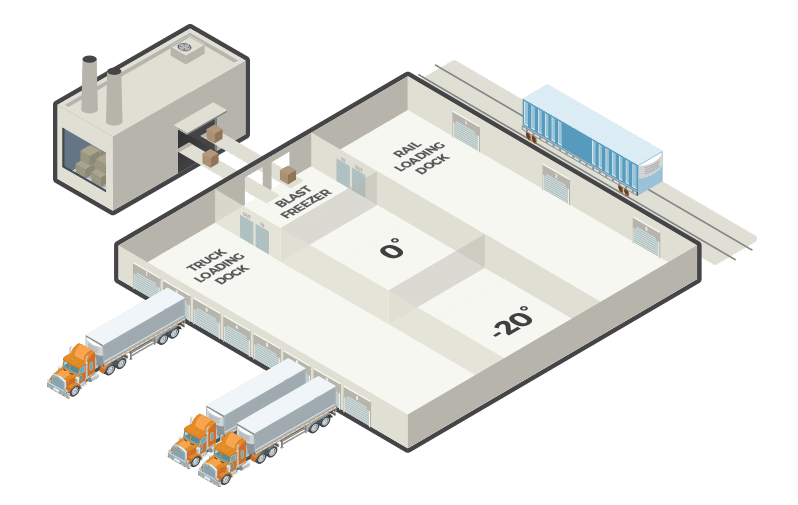

Customer-advantaged site

These facilities are typically physically attached, by a door or conveyor, or very close-by to customer production facilities. The dedicated sites offer significant time-savings in transportation, sorting, packing, blast-freezing, and storage due to their close proximity. Many offer rail connections to enable large-volume product distribution.

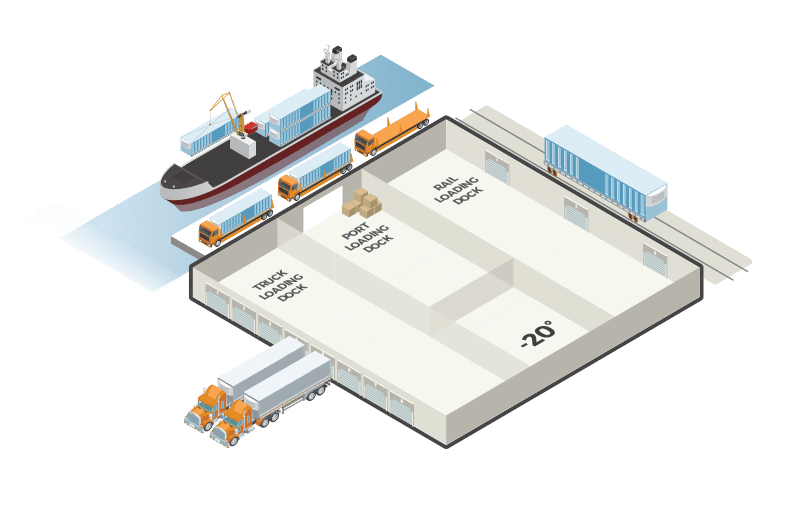

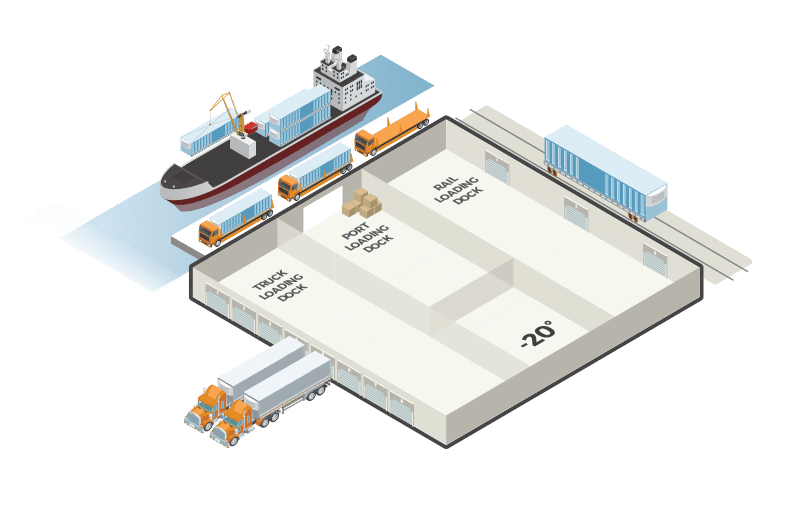

Port facilities

Situated close to major ocean ports, these sites offer container loading/unloading, drayage, inspection and documentation support, cross-docking, and some transloading services to support importing and exporting customers. We even have sites in heavyweight corridors to handle densely-packed containers.

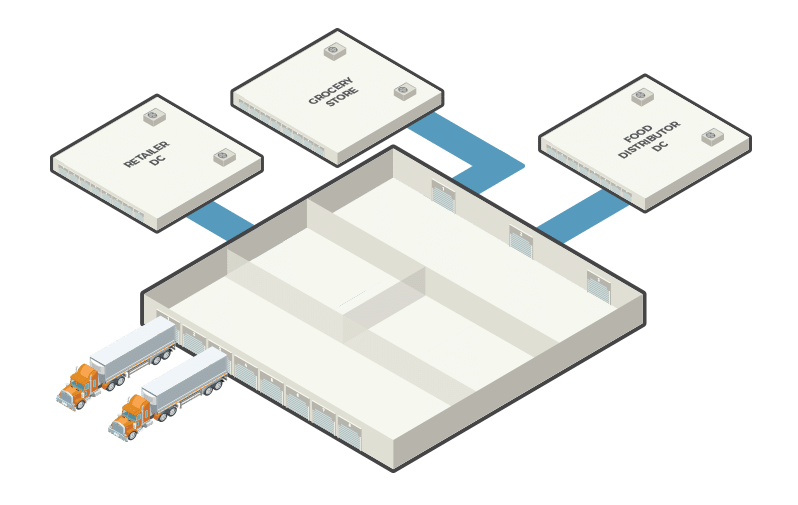

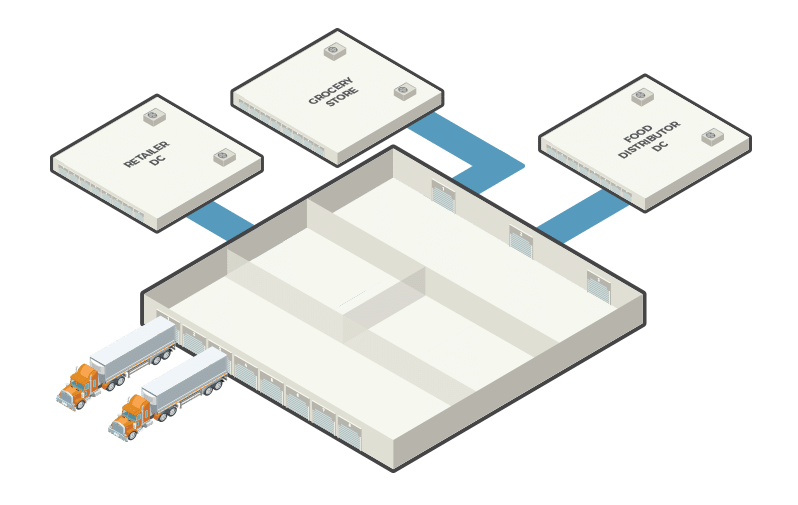

Regional consolidation centers

These facilities are the regional hubs for our transportation programs. We build truckload consolidations that depart on scheduled trucks calling on every major food retailer and food distributor DC in the region. Strategically located to optimize transportation routes and our customers’ delivery destinations, we also shuttle between Regional Consolidation Centers so that you can deliver in to one center but benefit from our national delivery network – perfect as you grow regionally and nationally.

Customer-dedicated (managed) site

Maybe you’d prefer to own the real estate but still want to benefit from our experience and Americold Operating System by utilizing our Associates, Management, and Processes. We can do that too. We bring AOS to you to coordinate facility operations, allowing you to focus on your own core activities.

Frequently asked questions

VIEW ALL FAQSWhere does Americold have Facilities?

Visit our Facilities page to see a map of our locations and see which one is closest to you and your business.

Does Americold lease or own its facilities?

Americold primarily owns its facilities, though in some cases Americold provides staff for customer-owned facilities or leases buildings if that’s a better fit for a specific program or location. Learn more about our sites on our Facilities page.

Can Americold manage a pallet provider program for its customers?

Yes, Americold can manage your pallet program for both inbound and outbound pallets as well as provide weekly reconciliation with the pallet provider team.

What ancillary/value-added services does Americold provide?

Americold offers a full range of ancillary/value-added services for its customers – the following are just a few examples: manifesting/take weights, slatting & de-slatting, manual order entry, USDA Services, case and each picking, aisle-ready pallet preparation, date stamping, light processing, blast freezing, and tempering. Discover more by clicking here . We can develop new processes and services to compliment your products as well – you have only to ask.

Ready to get started?

Contact us online or call us at 678-441-1400