Automation

Americold integrates automation into tailored, customer-driven solutions. Purposefully designed, rationally deployed automation enables a faster, safer, more transparent cold chain, helping customers improve service, reduce risk, and scale with confidence.

Innovation with Impact

At Americold, we believe there’s no one size fits all approach to automation. We take the time to understand your business’s unique needs and design automated solutions that solve your real operational challenges. Our systems reduce handling time, strengthen product safety, and yield real-time visibility so customers gain clearer, actionable insights for every decision.

Across our global network, automation elevates safety, accuracy, and throughput while also enabling our teams to move into higher-skill roles tied to system care and precision. This blend of advanced tools and human oversight deepens trust, reduces errors, and strengthens service performance at every node.

Each automation solution is custom-calibrated to achieve our customer’s unique goals, accommodate any facility requirements, and maintain product temperature needs. We don’t deal in templated approaches; we deliver tailored answers.

Automated Solutions

Automation at all nodes

Mountville, PA

Automation at all nodes

Russellville, AR

Automation at all nodes

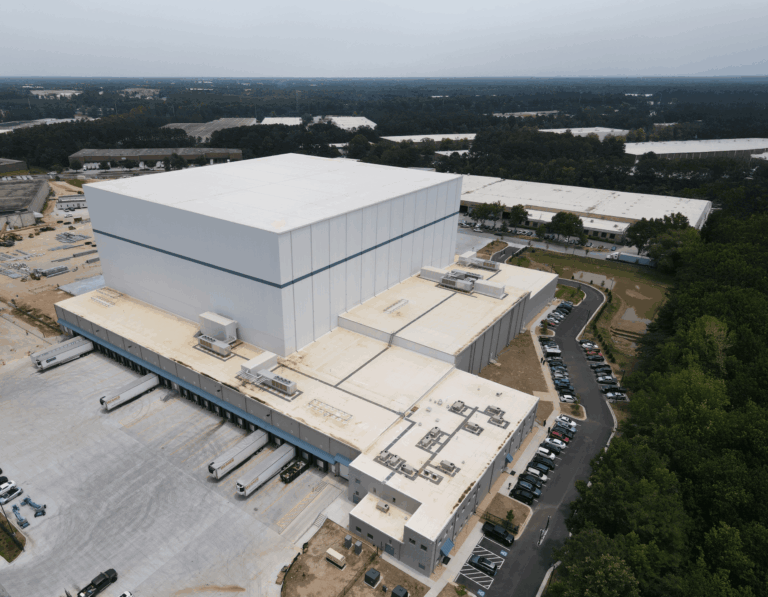

Gateway, GA

Let’s Do Better Together

Connect with our team and discover how Americold delivers the specialized solutions that help our customers feed the world.